Best Insulation is your Trusted Insulation Contractor for Austin, Texas

Best Insulation

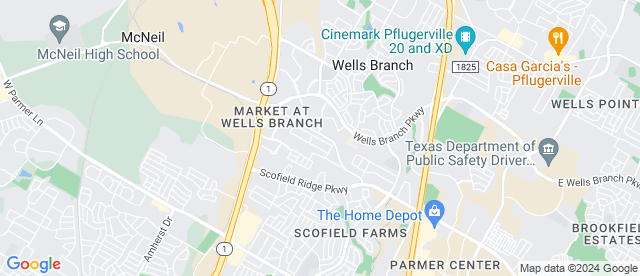

Branch Information

Branch Hours

| MON | 7AM – 4PM |

| TUE | 7AM – 4PM |

| WED | 7AM – 4PM |

| THU | 7AM – 4PM |

| FRI | 7AM – 4PM |

| SAT | Closed |

| SUN | Closed |

Leading Installation Services Near Austin

Best Insulation’s team of expert installers live and work in Austin, and we are dedicated to completing projects that improve our local community. We are located at W 2311 Howard Ln, Austin, TX and provide installation services for the Austin area. As a TruTeam company, we provide competitive pricing and best-in-class installation services. Call Best Insulation or complete our contact form for a free quote!

Who We Serve

Your Neighborhood Trusted Installation Contractors in Austin

As a homeowner, you can trust the installation experts at Best Insulation to be your partner on any home improvement project. Our installers live and work locally in the Austin area, and as a TruTeam company, we have the added advantage and resources of a national company and distribution system. Use our products and installation skills to improve your home’s value and comfort. Contact Best Insulation today to learn more about our comprehensive residential installation services.

A Trusted Local Installation Company for Commercial Builders in Austin

There’s no commercial building project too big or too small for the installation professionals at Best Insulation in Austin. As a local TruTeam branch, we are a trusted member of the community, and we have successfully completed thousands of commercial installation projects. We can scale quickly, keeping your project on budget and on schedule. Contact Best Insulation today to learn about our turnkey commercial installation services.

The Team You Can Trust

Get Free Quote

Nationwide

Network

Safety First

Culture

Thousands of

Expert

Installers

Installers

Millions

of Projects

Completed

Areas We Serve

Serving the greater Austin Area